Needle marking system e10-p123-25

For the efficient and permanent marking of your products of all kinds made of metal, plastic, wood, etc.

The marking system is characterized above all by its robust and industrial-grade design.

according to the following specification:

Marker head

Handheld device with pistol-shaped handle

X-axis with linear guide and ball-bearing slide, drive via

Rack and pinion, Y-axis swivel drive via rack and pinion

rubberized front plate for position fixing with V-recess and

Quick adjustment for workpiece distance

Labeling area 120 x 25 mm, LED lighting

Electromagnetic needle drive with needle guide and 60 mm embossing needle made of hard metal

Embossing possible up to 62 HRC material hardness

Maximum height adjustment of 5 mm, depending on the embossing force.

Noise level 76 dB (measured at medium embossing force and speed on sheet steel)

7.5 m control cable to the control unit with cable bend protection

Weight 3.7 kg

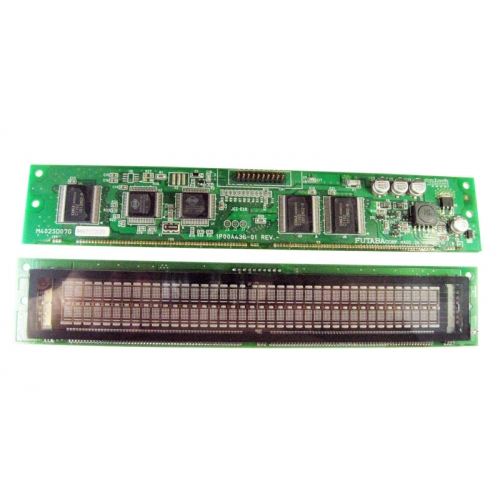

control unit

Integrated membrane keyboard, high-resolution color display (480x272 pixels)

USB interface; a special USB driver is required.

RS 232 and RS 422 interface

Ethernet and gateway for Profibus optional

Signal exchange via potential-free contacts, start/stop unit

Weight 5.0 kg

software

Font height adjustable from 0.5 to 25 mm

Dot matrix: 5x7 and 9x13 dots per character, variably adjustable dot spacing from 0.05 to 1.0 mm

Straight line, circle and angle labeling

Multi-line lettering possible in one embossing file

inverted and mirror writing

Fonts: OCR, OCR-A, Arial and Courier

Serial numbers ascending and descending, time variables, layers

Data Matrix Identification (ECC200),

Logo embossing (PC software for logo creation sold separately)

Preview and simulation of the minting process

Up to 2000 embossing files can be programmed.

Calling up 63 programmed files, BCD encoded

Serial communication using the ASCII protocol, text protocol, and binary protocol.